Electromagnetic sheet metal forming

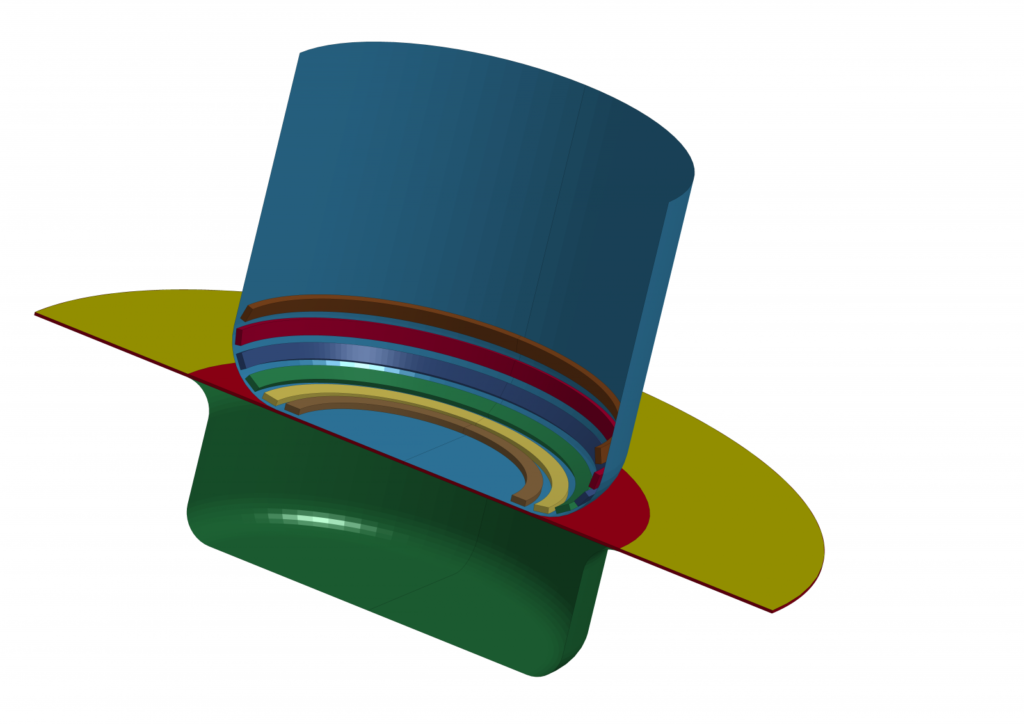

Electromagnetic sheet metal forming is a high-speed, contact free process. Eddy currents are induced in metallic workpieces by pulsed magnetic fields. The resulting Lorentz force causes the workpiece to be deformed. The required magnetic fields with peak values of a few Tesla are generated by discharging a capacitor bank into a tool coil, with the coil current typically increasing to values around 30,000 A within a time of 10 µs. The entire process duration is on the order of 100 µs. Electromagnetic forming as a single process is only efficient in a few cases, e.g. when joining tubular workpieces. On the other hand, electromagnetic forming is ideally suited for expanding classic shaping limits in the context of a combination with other quasi-static processes, such as classic deep drawing. Together with partners from manufacturing (IUL Dortmund), materials science (IW Hannover) and mechanics (IFAM Aachen), we are working on the description and optimization of such coupled processes as part of the DFG PAK-343.

Letzte Änderung: 29. Juni 2021