Wireless Network Safety & Security

Roaming Wireless Safety Emergency Stop

Motivation

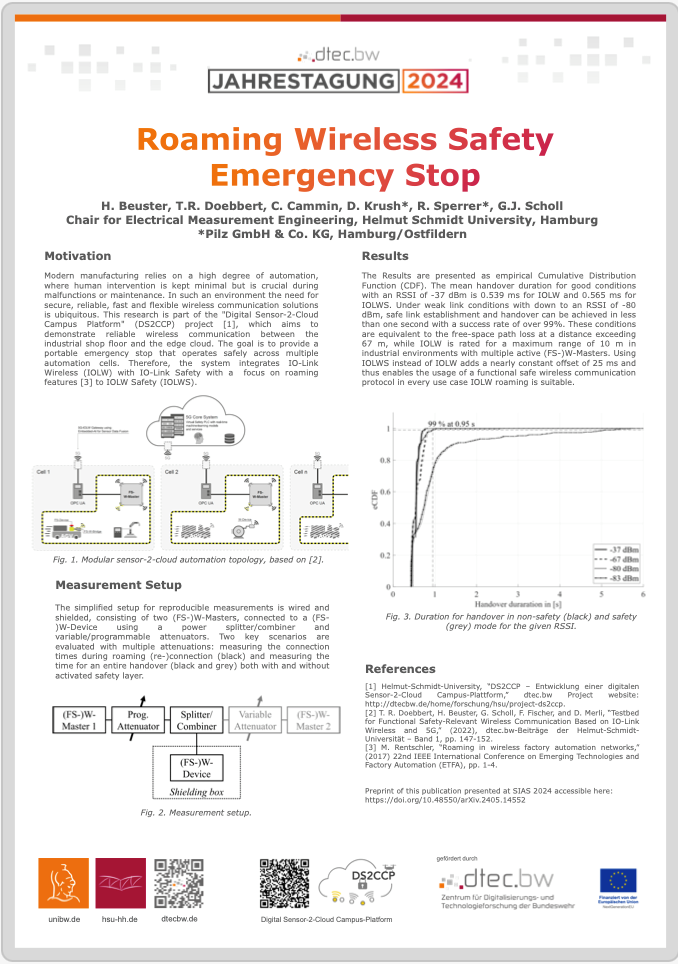

Modern manufacturing relies on a high degree of automation, where human intervention is kept minimal but is crucial during malfunctions or maintenance. In such an environment the need for secure, reliable, fast and flexible wireless communication solutions is ubiquitous. This research is part of the “Digital Sensor-2-Cloud Campus Platform” (DS2CCP) project [1], which aims to demonstrate reliable wireless communication between the industrial shop floor and the edge cloud. The goal is to provide a portable emergency stop that operates safely across multiple automation cells. Therefore, the system integrates IO-Link Wireless (IOLW) with IO-Link Safety with a focus on roaming features [3] to IOLW Safety (IOLWS).

Security in Private 5G Campus Network

Abstract

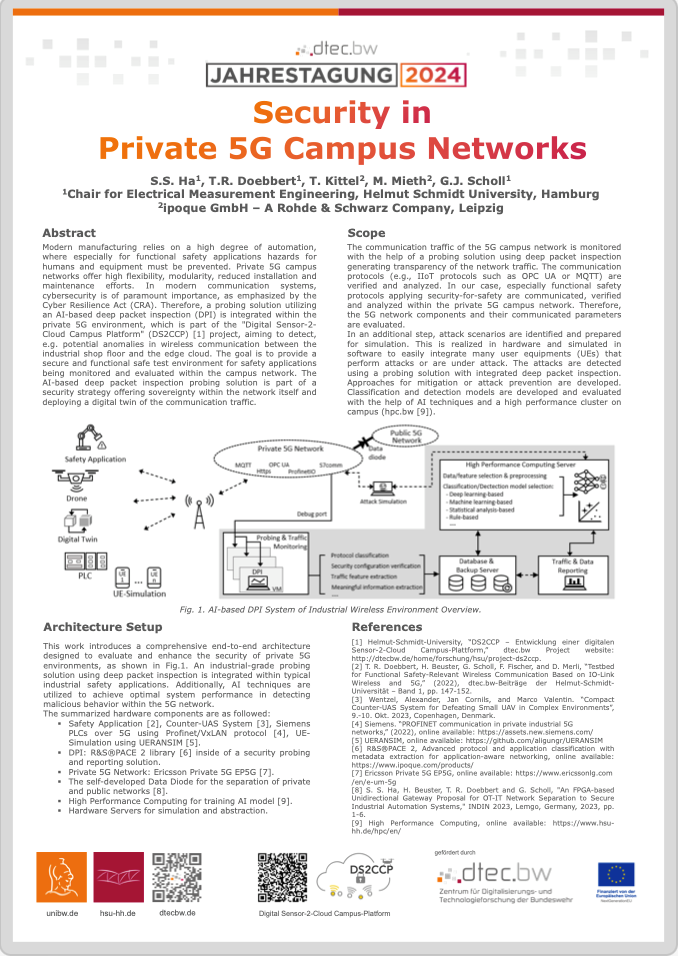

Modern manufacturing relies on a high degree of automation, where especially for functional safety applications hazards for humans and equipment must be prevented. Private 5G campus networks offer high flexibility, modularity, reduced installation and maintenance efforts. In modern communication systems, cybersecurity is of paramount importance, as emphasized by the Cyber Resilience Act (CRA). Therefore, a probing solution utilizing an AI-based deep packet inspection (DPI) is integrated within the private 5G environment, which is part of the “Digital Sensor-2-Cloud Campus Platform” (DS2CCP) [1] project, aiming to detect, e.g. potential anomalies in wireless communication between the industrial shop floor and the edge cloud. The goal is to provide a secure and functional safe test environment for safety applications being monitored and evaluated within the campus network. The AI-based deep packet inspection probing solution is part of a security strategy offering sovereignty within the network itself and deploying a digital twin of the communication traffic.

Robustness Testing for Embedded Devices Against DoS Attacks

Motivation

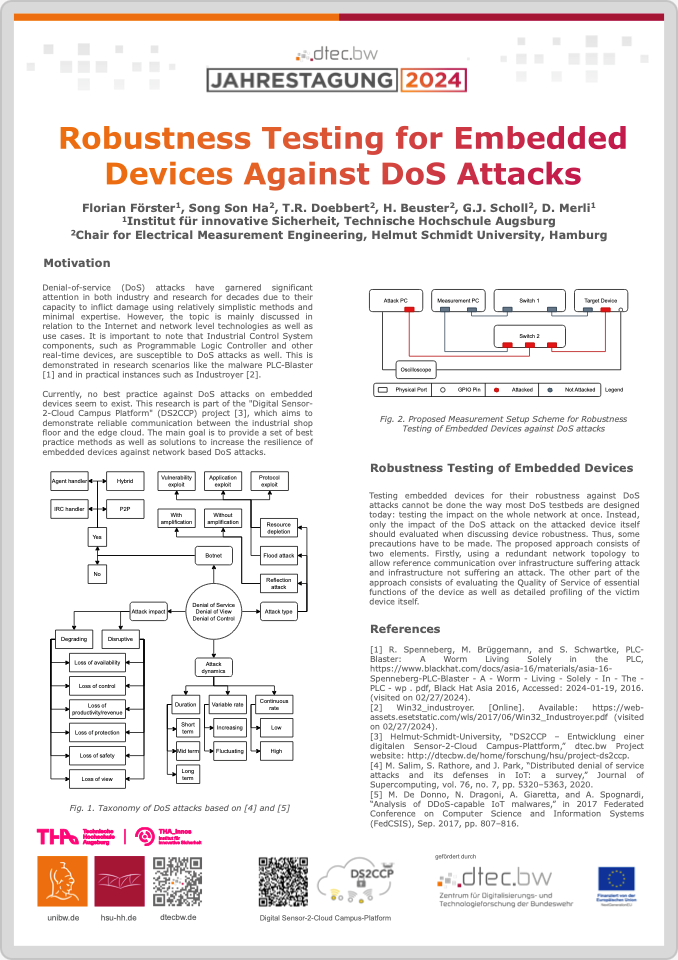

Denial-of-service (DoS) attacks have garnered significant attention in both industry and research for decades due to their capacity to inflict damage using relatively simplistic methods and minimal expertise. However, the topic is mainly discussed in relation to the Internet and network level technologies as well as use cases. It is important to note that Industrial Control System components, such as Programmable Logic Controller and other real-time devices, are susceptible to DoS attacks as well. This is demonstrated in research scenarios like the malware PLC-Blaster [1] and in practical instances such as Industroyer [2].

Currently, no best practice against DoS attacks on embedded devices seem to exist. This research is part of the “Digital Sensor-2-Cloud Campus Platform” (DS2CCP) project [3], which aims to demonstrate reliable communication between the industrial shop floor and the edge cloud. The main goal is to provide a set of best practice methods as well as solutions to increase the resilience of embedded devices against network based DoS attacks.

Accuracy Evaluation of SBOM Tools for Web Applications and System-Level Software

Motivation

Recent vulnerabilities in software like Log4j [1] raise the question whether the software supply chain is secured sufficiently. Governmental initiatives in the United States (US) [3] and the European Union (EU) [3] demand a Software Bill of Materials (SBOM) for solving this issue. An SBOM has to be produced by using creation tools and it has to be accurate and complete. In the past, there had been investigations in this field of research. However, no detailed investigation of several tools producing SBOMs has been conducted regarding accuracy and reliability. For this reason, we present a selection of four popular programming languages: Python, C, Rust and Typescript. For web application software we consider Python and Typescript while for system-level software C and Rust are investigated.

Security Considerations for IEEE 802.1 Time-Sensitive Networking in Converged Industrial Networks

Abstract

Cyber security becomes more and more relevant for the domain of Industrial Control System (ICS). An aspect, which increases the attack surface of those devices is the trend of Industry 4.0 and the associated network interconnections. While those devices were air-gapped and communication was clearly segregated, new technologies arise, which break up with this concept, since horizontal and vertical interconnection is essential for future use cases in ICS. Time Sensitive Networking (TSN) represents such a new technology, which allows the transmission of hard real-time traffic, commonly present within the field level communication, converged with other communication streams, e.g. non-time critical best-effort traffic, on the same wire. On the one hand this approach brings many benefits for ICS environments, e.g. predictive maintenance to reduce unplanned downtime, logging and others. But on the other hand this technology enlarges the attack surface of ICS and must therefore be analyzed from a cyber security perspective. For instance the transmission of real-time traffic can be disturbed easily by various network-based attacks, which makes protective measures necessary. Theretore, within this work, security considerations for the use of TSN within ICS applications are presented, suitable protective measures as well as potential enhancements are depicted. The threats and mitigations presented within this work are intended to draw attention towards cyber security within TSN based converged networks and provide an overview for possible protection strategies.

Wireless Sensor Network Applications

Cyber Physical Finite Element Sensor Network

Motivation

In modern manufacturing processes it is mandatory that the components to be manufactured are produced within well-defined tolerances. If only small production tolerances are permitted this often means that all production steps have to be monitored, which is a challenging task, e.g. in the production of large-scale components, where it is often not possible to determine the exact shape or surface stress in real-time during forming or deformation processes. Here, a standard solution is the use of laser trackers, typically requiring a human operator or a robot during the measurement process. Also, measurement time increases drastically with the size of the component. In this project we suggest an approach, where we measure the shape of an object with a finite grid of wireless sensor probes in real-time during the fabrication process. The sensor network measures the surface at discrete points in a similar way classical finite elements (FEM) discretize a volume for modeling the physical behavior. Hence, this measurement system is called a Cyber-Physical Finite-Element-Network (CPFEN).

Interferometry for Wireless Networks

Introduction

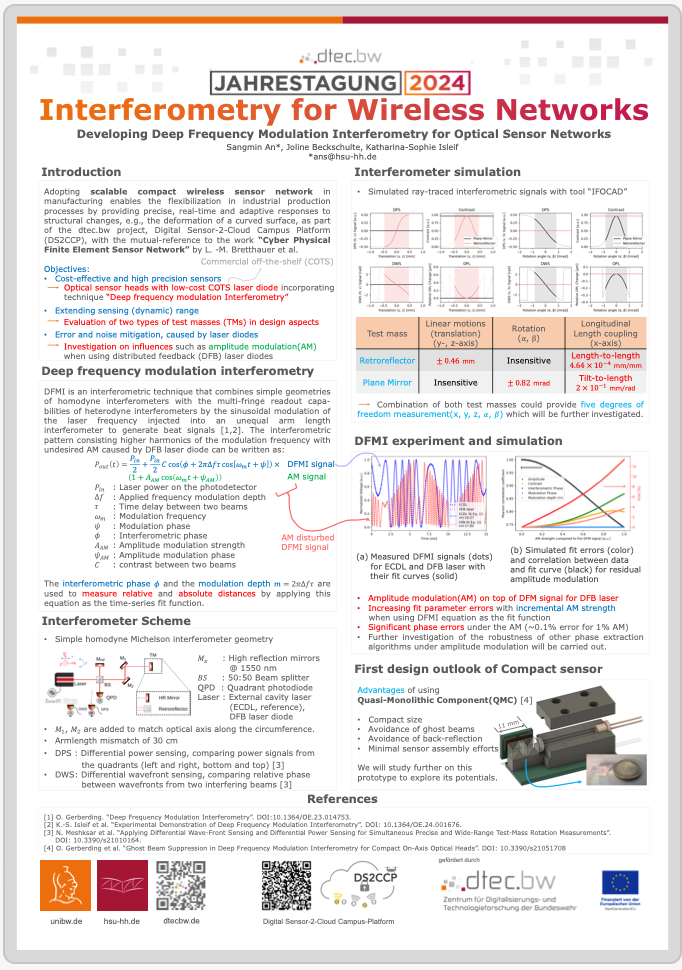

Adopting scalable compact wireless sensor network in manufacturing enables the flexibilization in industrial production processes by providing precise, real-time and adaptive responses to structural changes, e.g., the deformation of a curved surface, as part of the dtec.bw project, Digital Sensor-2-Cloud Campus Platform (DS2CCP), with the mutual-reference to the work “Cyber Physical Finite Element Sensor Network” by L. -M. Bretthauer et al.

Adaptive C-UAS Swarm with Ad-hoc 5G-SA Networks

Abstract

Threat scenarios with hostile Unmanned Aerial Vehicles (UAVs) are becoming increasingly difficult to handle. Additional to the variety of UAV types with their different capabilities, the situation will become even more difficult when Global Navigation Satellite Systems (GNSS) are occasionally jammed or unavailable [1]. Therefore, C-UAS (Counter-Unmanned Aerial Systems) need to have a robust communication for a reliable operation. Our C-UAS solution, where multiple UAVs interact to prevent a potential threat, operates agile and autonomously to cover a broad range of scenarios also in hostile environments. By using an ad-hoc 5G airborne network with AI-based carrier selection, swarm communication in jammed environmefrequencynts will be feasible. Communication traffic will be exchanged between Public 5G Mobile Networks and the Private HSU 5G Campus Network, established under the dtec.bw-DS2CCP project [2].

UAV Detection with Color and Infrared Images in the 5G Network

Project Overview

- Detection of unmanned aerial vehicles (UAVs) on color and infrared camera images through machine learning

- Transmission of image and control data between camera and processing computer via the 5G campus network

Letzte Änderung: 30. August 2024