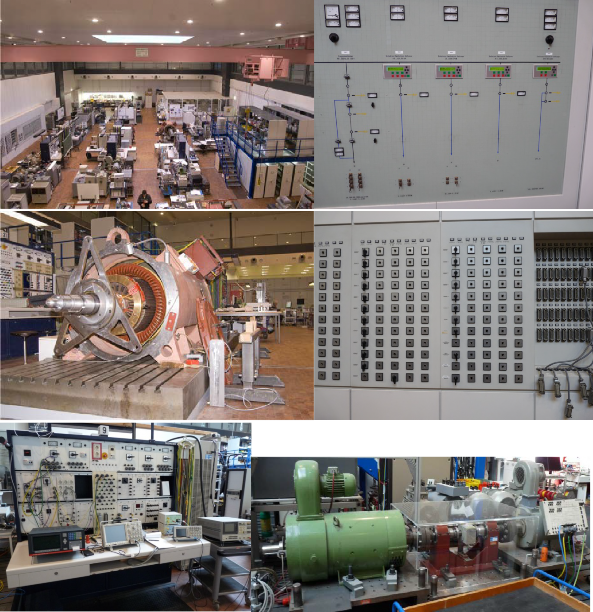

Laboratory of the Chair of Electrical Machines and Drive Systems

The electric machine laboratory consists of a workshop with a 5t assembly crane. Via a driveway and floor hatches, devices with large dimensions and weights can be transported into the hall. In the laboratory, 12 clamping plates for experimental setups are available.

Illustrations of the laboratory: Overview image with workstations (top left), power supply (top right), test setup (center left),

crossbar distributor (center right), stress analysis workstation 9 (bottom left), test setup for machine characterization (bottom right)

The power supply of the test stands is provided by rotating converters located in the basement and a three-phase power supply per workstation. The distribution to the test benches is done via a crossbar distributor. Furthermore, a number of static converters are available for the test benches.

Rotating converters:

- 3 Phase power supply, rating 3 x 63A

- 3 phase variable transformer 0 – 500V, 50kVA

- DC 0 – 440V, 50kW

- Frequency converter 100 – 500Hz, 20 – 500V, rating app. 50kVA

- Frequency converter 15 – 100Hz, 20-500V, rating appr. 50kVA

Static converters:

- Bidirectional 3-phase power supply 10 – 1000Hz

- DC power supply 0 – 500V, 0 – 600A up to 40kW

- 3 phase power supply 45 -5000 Hz, 15kVA

- 3 phase power supply realized by a linear amplifier 0 – 30kHz, up to 15kVA

- Several electronic loads for DC

- 4-Quadrant linear amplifier (Hubert), 250W, 2 channels 0 – 1MHz

The image shows static converter, linear amplifiers by Spitzenbergerg & Spieß , Heiden Power and ELGAR as well as DC-

power-sources and sinks

Measurement Equipment:

- Power Meter Yokogawa WT1800 ( up to 6 channels)

- Power Meter Norma 4000, 6000

- Torque measuring flange HBM 2 -500Nm for several rotational speed ranges

- Function generators (Tektronix and HP)

- Mixed Signal Oscilloscopes

- Data Recorder by HBM

- SLM SCADAS Mobile

- Dynamic signal analyzer HP 3562A

- Teslameter

- Thermocamera

The image shows several measurement devices (power meter oscilloscopes, signal analyzer, RMS

multimeters).

Testbenches:

- ETA4000 up to 10.000 rpm, 4kW, vector control load machine

- Chassis dynamometer for Ranger vehicle

- Test bench for super conductors (cyro pump for 40W of power loss, vacuum chamber ( up to 3×10-2 mbar

- Several pendulum machines for torque measurement

- High speed test bench for machines up to 50.000rpm, Magtrol eddy current brake

- Modal analysis system Siemens LMS Scadas using 24 piezo PCB triaxial sensors

- Balancing machine

- Universal test bench (Testometric) for measuring forces up to 10kN, tensile, compressing and flexural test

The image shows the balancing machine ETA4000, chassis dynamometer, eddy current brake, servo motor with HBM torque sensor

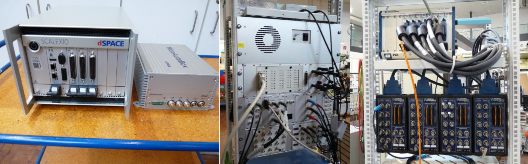

IT-equipment:

- dSPACE HIL Systeme, SCALEXIO, DS1005

- Simulation workstations, 40 cores, 1TB RAM, Nvidia Tesla V100

The image shows dSpace SCALEXIO systems (left), dSpace DS1005 (center), National Instruments PXI Box (right)

Simulation Software:

- Malab, Simulink, Toolboxen

- FEM ANSYS Workbench, academic research Maxwell 2D/3D, RMxprt ANSYS STRUKTURS, ANSYS FLUIDS, ANSYS ELECTRONIKS

- PSS SINCAL / Netomac

- LMS Test Lab

- Labview

- dSPACE ControlDesk

- Solidworks academic research

Letzte Änderung: 4. January 2021